Sprayed vermiculite is a type of insulation material that is used to provide fireproofing to buildings. It is made from a naturally occurring mineral called vermiculite that is mined from deposits located around the world. The origins of sprayed vermiculite date back to the early 20th century when the material was first used as an insulation material.

History

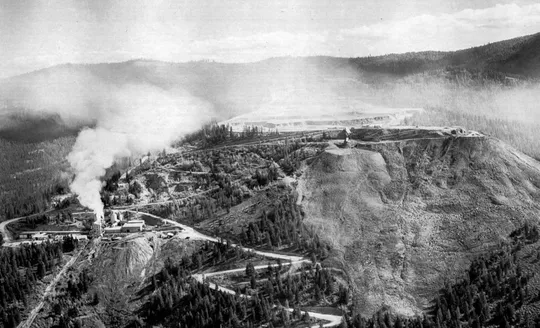

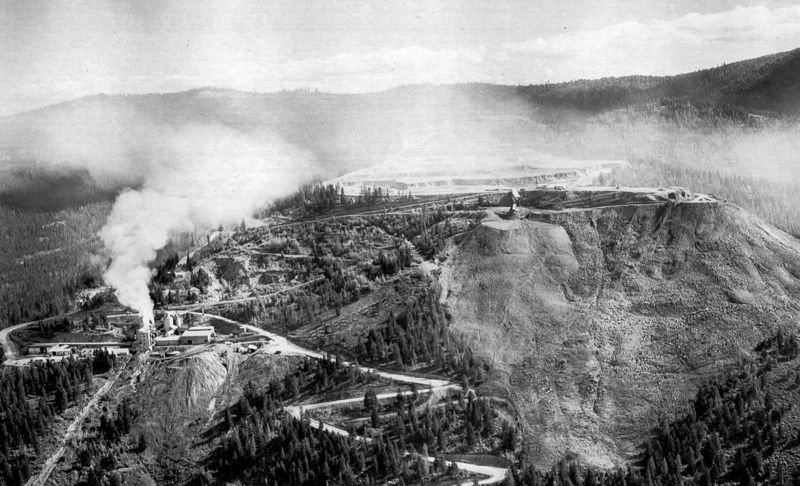

The first vermiculite mine was opened in Libby, Montana, in the 1920s. The mine was initially opened to extract the mineral for use as insulation, but soon

vermiculite began to be used in a wide range of other applications, including agriculture, construction, and even as a raw material for fire-resistant coatings.

During World War II, the US government recognised the importance of vermiculite as a strategic mineral for its unique properties and began to stockpile it. This led to increased demand for the mineral and the opening of new mines across the United States.

In the 1950s, the vermiculite industry experienced a breakthrough when it was discovered that the mineral could be expanded by heating it. This expansion process produced a lightweight and highly absorbent material that was ideal for insulation and horticultural applications.

By the 1960s, vermiculite had become a major industry in the United States, with large-scale mining operations in Montana, South Carolina, and Virginia. The Libby mine alone produced over 80% of the world’s vermiculite supply.

Vermiculite and Asbestos contamination

However, the success of the vermiculite industry was soon overshadowed by a tragic incident that occurred in Libby, Montana, in the late 1990s. It was discovered that the vermiculite from the Libby mine was contaminated with asbestos, a highly toxic mineral that can cause cancer and other serious health problems. The contamination was the result of natural deposits of asbestos that were present in the same rock formation as vermiculite, as both minerals develop under similar conditions. For decades, the mine operators and the government agencies responsible for regulating the industry had failed to recognise the danger of the asbestos contamination and take appropriate action to protect the workers and the surrounding community.

As a result of the contamination, thousands of people in Libby and the surrounding area were exposed to asbestos, leading to a public health crisis. The incident led to a major clean-up effort and a legal battle that resulted in the bankruptcy of the mine operator and the establishment of a trust to compensate the victims.

Despite its effectiveness as a fireproofing material, sprayed vermiculite has come under scrutiny in recent years due to concerns over its potential health risks. When sprayed, vermiculite can release small fibres into the air, which can be inhaled and cause respiratory problems. This has led some manufacturers to develop alternative fireproofing materials that are considered safer, such as cementitious coatings and intumescent coatings.

Advantages

One of the key advantages of sprayed vermiculite is that it can be applied to virtually any surface, including walls, ceilings, and floors. This makes it an ideal material for use in areas where fire protection is critical, such as stairwells, mechanical rooms, and other spaces that are difficult to access.

Another advantage of sprayed vermiculite is its ability to expand when exposed to heat. When sprayed, vermiculite forms a thick, porous layer that can absorb heat and prevent it from spreading. In the event of a fire, the vermiculite layer can help to protect the underlying structure, giving occupants more time to escape and firefighters more time to respond.

Conclusion

In conclusion, the origins of sprayed vermiculite can be traced back to the early 20th century, when the material was first used as an insulation material. Over time, it became a popular choice for fireproofing in the construction industry due to its effectiveness, versatility, and ease of application. While concerns over its potential health risks have emerged in recent years, sprayed vermiculite remains a viable and effective option for many building applications.